RVP and Pressure Vapor

I’ll bet most of you know that fuel doesn’t burn unless it forms vapor. For this reason, some fuel vapor formation is good. If too little vapor forms – in other words, evaporates – your race engine won’t start. If too much fuel evaporates, other problems such as vapor lock can occur.

In the world of fuel manufacturing and testing, the term “vapor pressure” is used quite a bit. Vapor pressure simply refers to the pressure created in a closed chamber by fuel vapor at a given temperature. Measuring vapor pressure allows us to quantify and compare a fuel’s tendency to form vapor. Reid Vapor Pressure, or RVP, refers to a standardized laboratory test that measures vapor pressure at 100F. ASTM International, formerly known as the American Society for Testing and Materials, has several test procedures which dictate protocol for standardized laboratory testing of fuel vapor pressure including RVP.

Higher RVP means the fuel forms more vapor… in other words, more fuel evaporates at 100F. Obviously, a lower RVP indicates less fuel evaporates at 100F. RVP is also one of the many fuel parameters covered by federal, state and local emissions regulations since changes in RVP correlate to changes in evaporative fuel emissions.

The RVP of pump gas in the US can range from about 6 to 15 psi and is adjusted seasonally and regionally and reflects both temperature and regulatory changes. When and where temperatures dip, RVP is increased to promote better cold starts. In the summer, pump gas has a lower RVP to stave off vapor lock, a problem that can arise when fuel gets too hot.

Now that you know that RVP is lowered to minimize heat-related problems, you can understand why most race fuels have a lower RVP for better heat resistance in hot racing engines. Race fuel RVP values under 6 psi are common.

Not all racers want low RVP fuels, however. Some, especially those in colder climates, may want a higher vapor pressure fuel, so they pay attention to RVP. While this is a good first step, there is much more to it than RVP alone. RVP does not tell the full story of fuel evaporation.

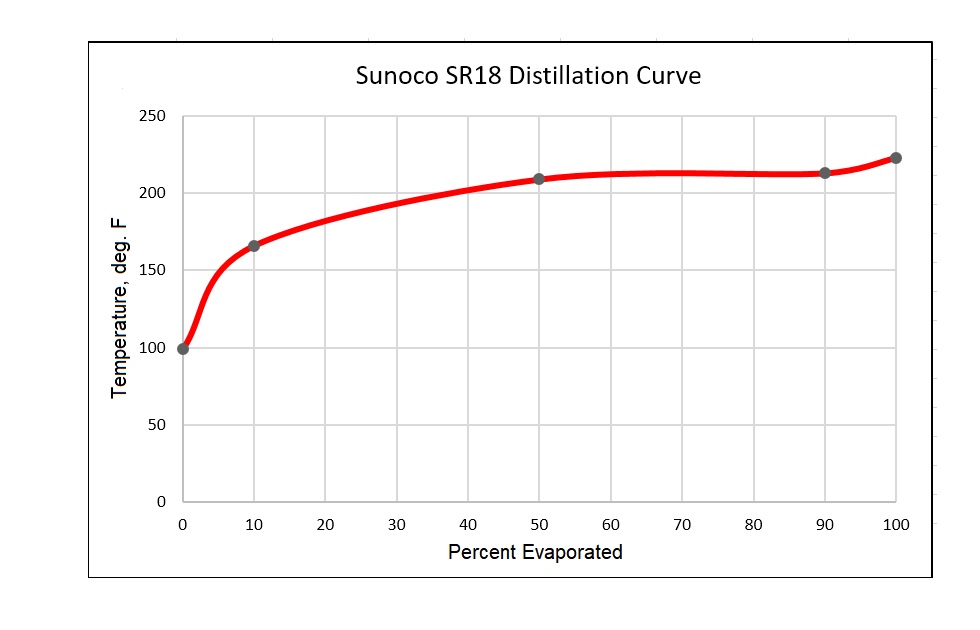

First, you need to understand that a fuel is made up of many different hydrocarbons. Each of those individual hydrocarbons evaporate, or “boil”, at different temperatures. Simply put, they have different boiling points. So a fuel will start to evaporate at a relatively low temperature as the lower boiling point hydrocarbons begin to evaporate; this is known as the Initial Boiling Point (IBP). A fuel will finish evaporating at a much higher temperature when the higher boiling point hydrocarbons finally evaporate. This is known as the Final Boiling Point (FBP), or the End Point. A fuel’s boiling range covers the temperatures from IBP to FBP and the curve made by plotting all the data between IBP and FBP is often called a fuel’s boiling curve or, more commonly, distillation curve. The lab test used to determining a fuel’s distillation curve from IBP to FBP and all the points in between is called - you guessed it - a distillation test.

Why do we mention IBPs and FBPs in a tech article about vapor pressure? Well, that’s a good question. Let’s see if we can provide an answer.

Pump gas properties vary quite a bit, so characterizing them is challenging, but let’s say they typically have boiling ranges of about 80F to 400F. By design, most race fuels have a much narrower boiling range. For example, Sunoco SR18 has a boiling range of about 100F to 220F. So that means SR18 is just beginning to generate vapor right at 100F. But, remember, the RVP test is performed at 100F… right at the IBP. The result is that an insignificant shift in IBP can result in a major change in RVP. While the RVP test might be OK for pump gas, it is often on the edge of the boiling range of a racing fuel… and sometimes outside the range. This is why focusing on RVP can be misleading when we’re talking about racing fuels. The RVP test looks at only one temperature point, while the distillation test looks at ALL the temperature points – the entire distillation curve.

Bottom line is this: you can’t represent a fuel’s evaporative characteristics with RVP alone. It’s only one data point at one temperature, and for many racing fuels it’s outside the useful range. You’re much better off knowing the distillation curve, which represents a fuel’s entire boiling range. This is why we share distillation curve data for each fuel on our website. In addition to IBP and FBP, you’ll see distillation curve parameters identified as T10, T50, and T90. The “T” means temperature and the number means percent. For example: T50 is the temperature where 50% of the fuel has evaporated per the distillation test, and so on. Check out the distillation curve for SR18:

This was a long article, but so many racers requested a better understanding of RVP that we felt we owed them a better explanation. As usual, if you need more info, or just want to chat about fuels, call us at 800-RACE-GAS or drop us a note in our Contact Us form.